The options and the benefits of intumescent coatings:

In the wake of the Grenfell Tower disaster and the Building Safety Act 2022, fire safety in buildings has become an even more important issue. It’s critical to understand fire protection to ensure robust fire prevention and protection systems. Intumescent coatings are a prerequisite in steel fire protection on new construction projects.

Prevention and protection are afforded in a number of ways, from active measures of effective containment or extinguishment systems, to having escape routes and alert systems in place. Additionally, employing passive protection measures supports a building’s resistance to fire in the event of an emergency.

Where a building is constructed using structural steel, intumescent coatings are one of the most effective ways of delivering passive fire-protection.

These are a paint-like material which protects the structure and integrity of steel in the event of a fire. If subjected to high temperatures, chemicals within the coatings swell and expand, preventing steel from reaching a critical temperature. By supporting the steel to maintain its load-bearing capacity it extends the length of time a structure can withstand fire and prolongs the time available for a building to be evacuated.

Intumescent coatings can be applied without compromising the steel’s own properties. However, because the paint expands under high temperatures, if it is to be applied to structural steel it must be planned at the earliest stages of the building design to safely accommodate expansion.

This impact on building design means understanding their application is the responsibility of more than just fire engineers and steelwork contractors, allowing architects and main contractors to bring in the right expertise at the right time.

As the use of intumescent coatings has grown in popularity industry leaders have outlined workable methods for contractors to use them and ensure adherence to both UK and EU rules and regulations on fire safety.

The British Constructional Steelwork Association’s (BCSA) latest National Structural Steelwork Specification for Building Construction includes information on intumescent coatings. The BCSA recognised this addition to its guidance to be vital following the Grenfell tragedy.

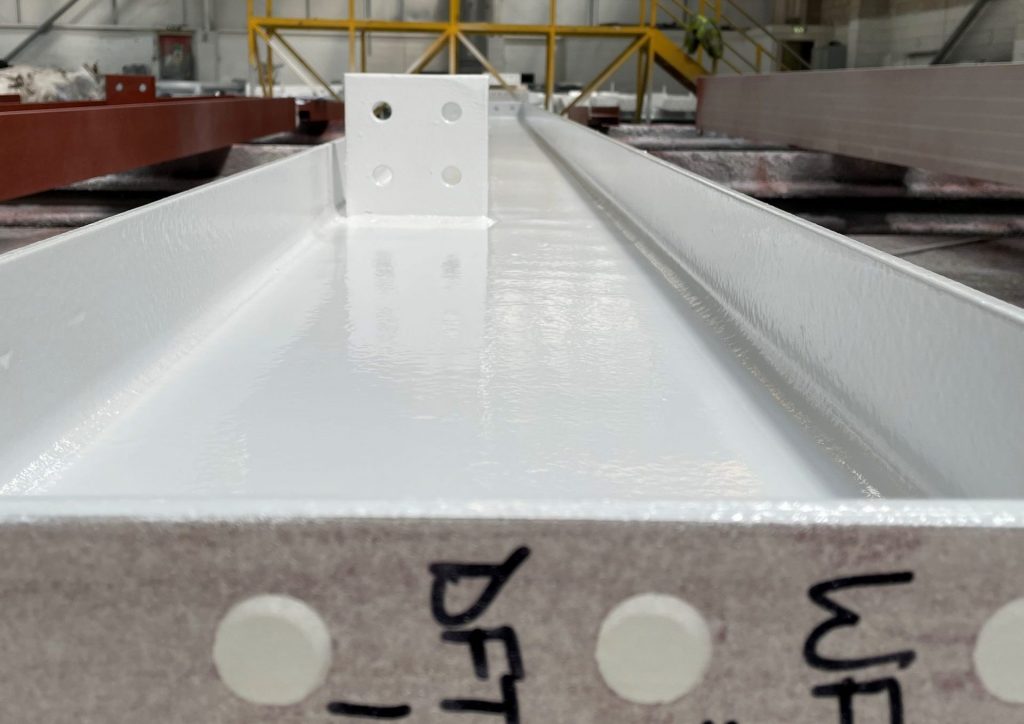

Intumescent coatings are most commonly spray-applied and this can take place both off-site and on-site, as either water- or solvent-based substances.

While the majority of applications take place on-site, often using a water-based solution, the BCSA encourages steelwork contractors to apply intumescent paint off-site, during the fabrication stage of structural steel. This allows for greater quality control and quicker construction and immediate safety benefits once on site. Because it is specialist work it creates higher up-front costs but its safety and time-saving advantages make it more cost effective overall.

Solvent-based solutions can be applied to wider range of section types and can also be used on-site, but more often for smaller sections requiring greater thickness and protection. Both types can also be used to give a decorative finish, if necessary, however this is usually more difficult to achieve using off-site application.

As intumescent coatings are become more prevalent in new steel constructions, understanding their uses and working with a steelwork contractor with experience in their application is essential.

Safety is the most important factor on any construction site. Discover more about practices and process to ensure safety

If you would like to keep up to date with the latest industry news and developments, sign up to our newsletter today.