On almost all projects, discussions and decisions on materials are some of the first to take place, whether that’s due to strict budgets or ambitious design ideas.

But if cost is the core consideration for a project a decision on material types won’t guarantee a definite quote on prices, due to insufficient detailed information and fluctuating prices of raw materials.

Thankfully though, for steel structures there is a way to be more certain of construction costs early on, through repetition and consistency. Understanding the cost implications of different structural frames can greatly inform costing early on – something experts in the design of steel structures can support with.

Investing in this expertise for design and detailing can also lead to reduction in overall pricing for a project.

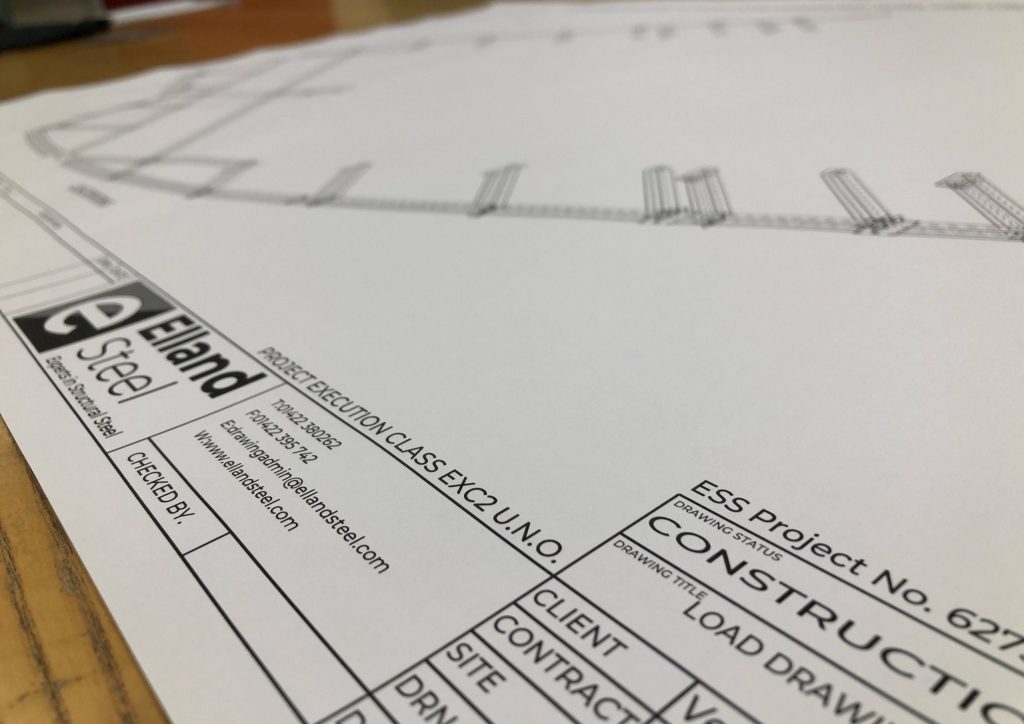

Structural draughtsmen, well versed in the commercial aspect of their detailing, can create a level of repetition and consistency in a structural frame design that will reduce steel costs thanks to less complexity in connection detailing or material choice. Because the accuracy of costing is dependent on the availability of information, a design that utilises repetition and consistency can support detailed, accurate budgeting.

Prefabricated steel structures can reduce overall costs by 2-3%, compared to concrete. But fittings and connections can still start to add up, accounting for a significant portion of a structural frame’s cost, despite making up little more than 10% of the frame’s weight. So repetition in their design and usage will deliver time and cost savings.

As fabrication and construction together make up 10-15% more of the overall framing costs than the materials themselves, simpler or standardised designs for high-storey buildings will reduce costs at these stages. Standardising the connection design – between horizontal beams and vertical columns – will reduce fabrication costs, with repetition allowing for reduced material costs and faster fabrication. And repetitive structures with standard components will also reduce erection time.

The cost of connections is largely based on their complexity, rather than weight, so finding a connection that works for a building and repeating it will be beneficial.

Experienced draughtsmen will have cost models that will help to inform not only the budget but also other elements of the project, such a logistics in the construction programme or the installation of services. These are likely to cover a range of building types and site conditions, from multi-storey steel structures to industrial frames – useful as site conditions, such as location of a new development or wind loading on the final building, can impact on connection design and costs too.

Investing in expertise like this intrinsically delivers overall savings by ensuring no costly surprises later on in a project.