The key details to consider when designing steel frames

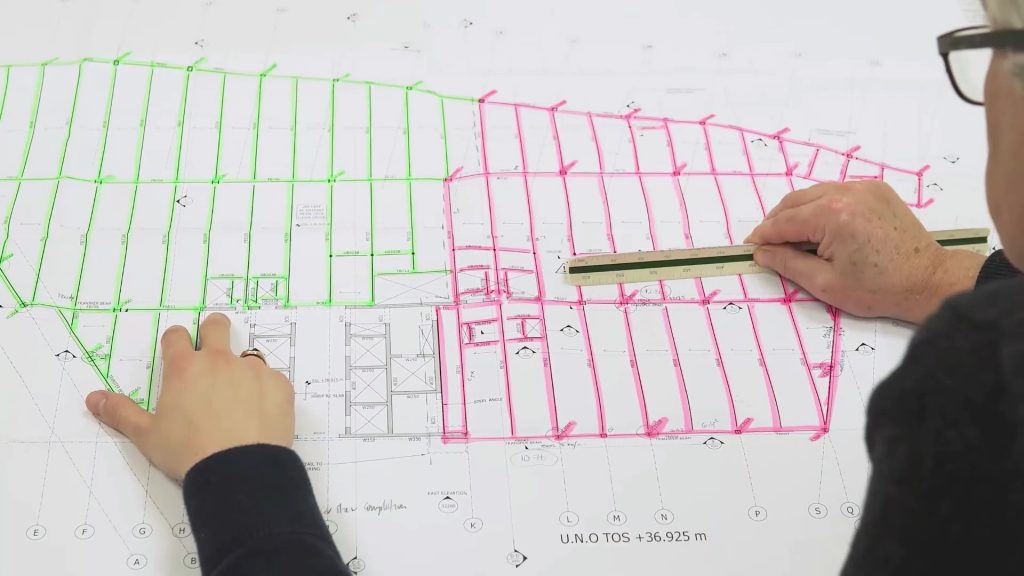

It’s all in the details. Big picture thinking is vital for structural engineers delivering builds, but the finer details of a project should also be appreciated.

Since the decisions taken during the design stage affect constructability, understanding the impact design details will have on programme timings and costings is advantageous.

A steel frames ‘constructability’ – the ease with which its structure can be built – will greatly impact its economic viability. Efficient, simple designs are conducive to easier, more economical builds.

Working in practical design details – with standardised connections, opportunities for pre-fabrication or requiring limited material types – will streamline the procurement process and fabrication work on-site.

5 key details to focus on during design:

1. Connection designs

Standardising connections will aid simpler fabrication and construction processes and create overall cost savings. For example, since flats are both easier and cheaper to source than plates (profiles), spending time incorporating these into the connection design will save time, energy and costs further down the line.

Complex connections can create costs for both fabrication and installation and can also have a knock-on impact on tolerances and interfaces. However, it is also important to strike a balance between the ease of standardised connections and not specifying arbitrary requirements of all connections, that create unnecessary costs.

For this reason, where appropriate, allowing the fabricators and contractors responsible for the structural steel to design and detail the connections is ideal. This can increase the opportunities for off-site prefabrication too, creating further time, cost and energy savings. To achieve this, accurate information on reactions, loading capacities, connection moments and member forces is essential.

2. Transparency

Sharing comprehensive information in a timely fashion is always key. Providing information to designers early on reduces the risk of multiple or ongoing technical queries and means less time spent clarifying detail or adjusting requests. As above, sharing information can allow steelwork contractors to share their expertise and complete detailed parts of the design. This allows for more accurate costings to be developed and submitted within budgets early on.

3. Bolts

As with the connection designs, standardising the use of bolts will make procurement easier, with cost savings highly likely, and reduce the risks of errors in-use during fabrication. As with all part of the steel frame, bolts must meet the requirements for strength and corrosion resistance, so standardising the use of zinc plates bolts, for use in internal environments and adopting galvanized or sherardized in external environments, then reducing the number of different diameters will reduce errors when installing bolts at height.

4. Steel fabrication

‘Fabrication friendly’ steel frames are vital to smooth project management. Good frame design includes understanding which elements of the frame will require painting or protective coating and considering the order in which columns, girders or beams will need to be moved into place. Both have a huge impact on programme constraints, costs and timings, impacting the ease of fabricating members, delivering and managing materials on-site, and then erecting, fabricating and painting or protecting members.

5. Welding structural steel

An understanding of the welding requirements for member designs can pay dividends during construction. Welders require adequate access to work on members. While factoring this in might seem obvious, it is sometimes missed, causing costs to quickly spiral. Additionally, the requirements for each weld’s preparation, passes and inspection should be understood. For example, certain welds require specific testing or inspection – such as magnetic particle inspection (MPI), to detect flaws, or local capacity checks – necessitating extra time or specialist personnel to complete.

The National Structural Steelwork Specification for Building Construction (NSSS) is a valuable resource for getting each of these aspects right. Its guidance has been developed, and is regularly revised and updated, to standardise approaches to designing and constructing steel frame structures.

Standardised, simpler designs will save on costs and time at every stage, limiting the need for multiple queries or changes during design, and reducing the risk of errors during build.

Thorough and regular information sharing that allows for an appreciation of the whole technical, manufacturing and erection process, will support good design and streamlined construction.

As the consulting Structural Engineer usually has the big picture on their mind it is easy to forget about the smaller details:

- Connection designs: creating practical design details that contain standardised materials for ease of procurement and fabrication. Flats are easier and cheaper to acquire than Plates (profiles)

- Bolts: again standardising the use of bolts say designing for one specific type i.e. M20 , eases procurement and reduces the risk of errors throughout the process.

- Fabrication: creating fabrication friendly frame design is a crucial aspect, this has a major impact on programme constraints, costs etc. by understanding the exact material grades , ease of fabrication of elements and then paint application, designs can be streamlined to improve manufacturing processes.

- Welding: appreciation of member designs and how they can be at a detriment to the access or quality of the weld. Understanding that certain welds require certain testing such as MPI or local capacity checks.

- Early stage information transparency: information is key, the more information the designers have at the earliest possible stage the less technical queries are required and the less time spent fetching clarifications.

In conclusion, good information exchange from an early stage can reduce the impact of poor design. Appreciating the whole technical, manufacturing and erection process can drastically save time, money and improve collaboration between interfaces.