A steelworker’s perspective on pricing retrofit projects

Retrofitting will play an important part in the construction sector meeting net zero targets.

Since around 80% of the building stock we’ll be using by 2050 is already built, bringing many of these properties up-to-date will require some substantial retrofits of both structures and systems. Existing buildings must be made more energy efficient or new needs met by bringing older properties back into use.

Structural retrofits cover work within a building’s fabric – like upgrading cladding or installing insulation – and to its frame – such as extending or reinforcing an existing structure. These works are often required to accommodate system retrofits, which cover improving or adding systems within the building. For example, strengthening a structure to support the weight of new roofing , cladding or external terraces.

When thinking about cost considerations for structural retrofits, there are some key points which need to be understood, and responsibility agreed upon, during the tender process. This ensures an accurate price can be given and that correct, safe processes are undertaken.

Surveying costs

Any retrofit must begin with a sound understanding of the existing building’s constraints, risks and opportunities – both those of its structure and also its location and surrounding infrastructure.

Investigations of the frame and facades using techniques like Ferroscan or vibration analysis identify factors like tolerances, foundations and pile capacity. Assessments of the location will look at access requirements and constraints, proximity to other structures or local infrastructure, and specific site conditions.

For any type of retrofit, insulation surveying is also essential, covering a number of challenging areas. Surveys must take into account balancing heating and condensation, and thermal bridging and heat loss within the new building.

All this requires comprehensive information gathering, with budgets allowing for adequate costs and timings. As well as creating more accurate project costs, thorough surveying will also provide information for realistic performance gains around end-usage and efficiency.

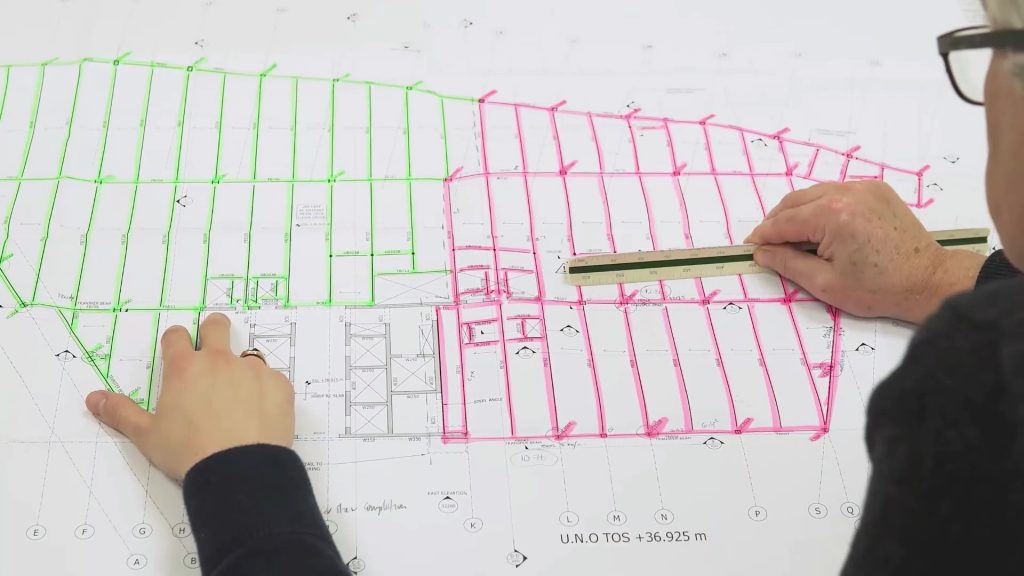

Surveying is especially prudent for works to reconfigure a building, where new structural steel will need to be connected to existing concrete or steelwork. Using both modern surveying techniques and historic building records is essential.

Understanding existing materials

Retrofitting is often more cost-effective than demolishing a property and building new; particularly when considering the heritage value in reinvigorating older buildings. To get these types of retrofits right, the existing materials must be identified and understood, including their current usage and anticipated requirements, to sympathetically rework and reimagine structures.

The existing materials should be identified, tested and understood in terms of their durability, exposure to the elements, and overall impact on energy efficiency. This will then impact the materials, methods and programme sequencing applied.

Similarly, when extending or upgrading existing buildings – adding multi-storey extensions, creating useful basements or repurposing layouts – thorough information and planning around existing materials is required.

This information can support the delivery of system retrofits too, allowing for comfortable incorporation of the service and maintenance systems required by the new development.

Connections to existing frames

Connections play a vital part in improving the capabilities or expanding the size of an existing structure. Working to connect and brace members while also transmitting forces, they are important to get right. Since they can influence 40-60% of a frame’s cost, they must be carefully considered in retrofits to ensure efficiency and effectiveness.

The existing connections, original frame type, steel grades and materials in place will largely dictate what is possible, along with the space and parameters for removing and replacing existing connections, where necessary. Often bolted connections are preferable in retrofits, since welding requires higher levels of information on the materials being welded to.

For structural retrofits to expand or reconfigure an existing building, the connections to existing frames must be carefully chosen. Where a buildings’ use is being changed increased loading or tolerances will be required from connections. And where the retrofit involves significant expansion, new connections will be required for new members, and existing ones upgraded to allow for increased capacity.

Connecting the costs

The investment of time and expertise in surveying and gathering comprehensive information will pay dividends in allowing for accurate costings and a realistic design.

Collaboration, open communication and early contractor involvement are key to these types of projects. The level of information, expertise and attention to detail required far surpasses that for a typical new-build project. But so too do the benefits.

Going beyond just environmental, the benefits can be economic and social too; by preserving and enhancing buildings. To enjoy these benefits, contractors must work closely together, sharing information and expertise to deliver progress and true sustainability.